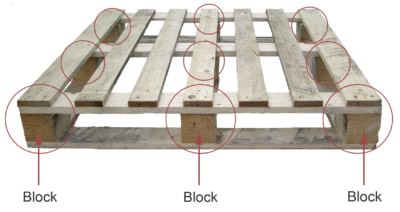

Block Pallet

The block pallet gets its name from the blocks that form its base. There are typically 9 blocks in a block pallet, with a solid wood block placed in each of the four corners, in the center of each side of the pallet, and in the center of the pallet itself to support the unit load.

A block pallet is also known as a “four-way” pallet because the tines of a pallet jack or forklift can access and lift it from all four sides of the pallet. Block pallets can be designed with or without bottom deckboards.

Block pallets are commonly thought to be stronger and more durable than stringer pallets because they utilize both parallel stringers and perpendicular blocks, but as you’ll see from the head to head test below, that’s not necessarily true.

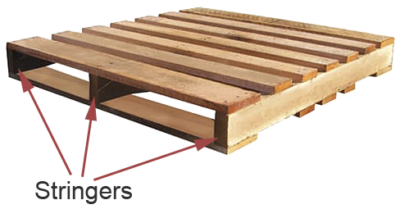

Stringer Pallet

Stringer pallets are the most commonly used pallets in the United States, and are so named because they use stringers to support the unit load. Stringers are the boards that are sandwiched between the top and bottom deckboards, and are typically made out of 2 x 4’s or 3 x 4’s.

Stringer pallets are generally thought of as “two-way” pallets, meaning a forklift or pallet jack can only access them on two sides, but stringer pallets can be notched (for a forklift) or chamfered (for a pallet jack) on the non-accessible sides to allow for four way entry. Although the most common size for a stringer pallet is 48” x 40”, they can be designed to virtually any size.